Building A Centre Console Wooden Fishing Boat.

When it comes to building wooden fishing boats, Tasmanian Huon Pine is highly valued in the marine woodworking community.

This unusual wood, which is indigenous to Tasmania’s rainforests, is well known for having remarkable qualities that make it a great choice for boat building.

Notably, Huon Pine is distinguished by its remarkable durability, attributed to the natural oils permeating the wood, which provide inherent resistance to decay and marine organisms.

These oils not only enhance the wood’s longevity but also reduce the need for frequent maintenance, a significant advantage for boat owners.

In addition to its durability, Tasmanian Huon Pine is celebrated for its workability. The wood’s fine, even grain allows for precise cuts and smooth finishes, making it a favorite among craftsmen.

This characteristic is particularly advantageous when creating intricate designs or ensuring seamless joins in a boat’s construction. Furthermore, Huon Pine’s stability is a critical factor in its suitability for marine environments.

The wood exhibits minimal shrinkage and expansion, even in fluctuating moisture conditions, ensuring that the boat’s structural integrity remains uncompromised over time.

An equally important attribute of Tassy Huon Pine is its lightweight nature. This feature not only facilitates easier handling and construction but also contributes to the overall performance and efficiency of the finished vessel. A lighter boat offers better buoyancy and fuel economy, enhancing the fishing experience.

Moreover, the aesthetic appeal of Tasmanian Huon Pine cannot be overstated. Its rich, golden hue and fine texture impart a timeless elegance, making each boat a work of art in itself.

The allure of using Tasmanian Huon Pine in high-end boat building lies in these combined qualities. Its blend of durability, workability, stability, lightweight nature, and aesthetic beauty sets it apart as a premium material for crafting dream wooden center console V-hull fishing boats.

Embracing this exceptional wood not only ensures a boat of superior quality but also connects the builder and owner to a tradition of excellence in marine craftsmanship.

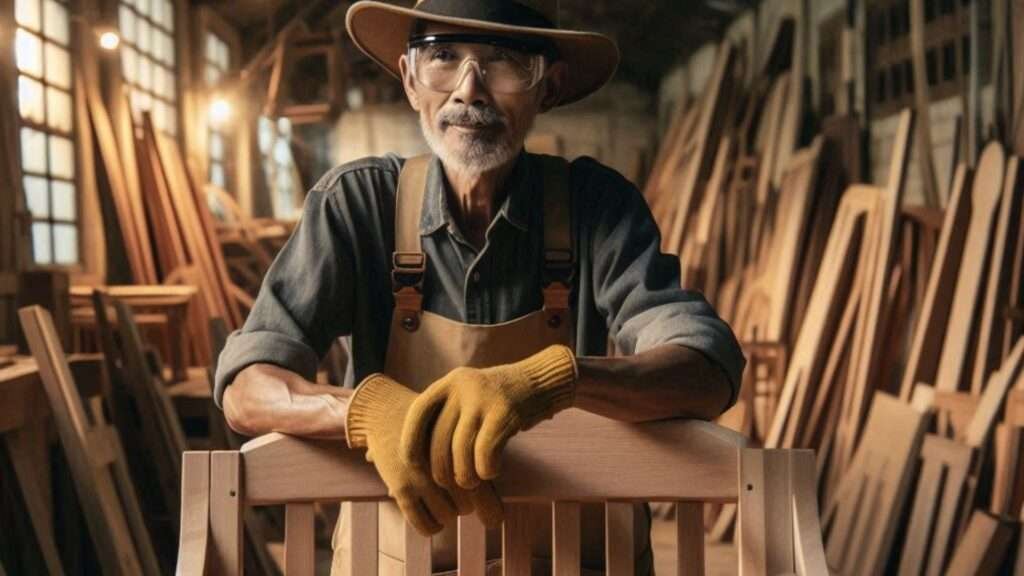

Mastering the Fundamentals of Wooden Boat Building.

Embarking on the journey of crafting a wooden center console V-hull fishing boat necessitates a comprehensive understanding of wooden boat building fundamentals.

This foundational knowledge is pivotal for ensuring the structural integrity and aesthetic appeal of the final product.

Central to this endeavor is the selection of appropriate materials and tools, with Tasmanian Huon Pine being a prime choice due to its durability, resistance to rot, and workability.

Firstly, selecting high-quality materials is imperative. Tasmanian Huon Pine, renowned for its longevity and natural oils, offers unparalleled benefits for boat construction.

Its fine grain and ease of shaping make it ideal for intricate boat designs, ensuring that your fishing boat will not only be functional but also enduring.

Additionally, other materials such as marine-grade plywood, stainless steel fasteners, and epoxy resin are essential for various stages of the build, providing strength and resilience against harsh marine environments.

Equally important is the mastery of essential boat-building tools. A comprehensive toolkit should include items such as saws (both hand and power), chisels, planes, clamps, and sanders.

Precision measuring tools like calipers and squares are crucial for accurate cuts and fits. Moreover, acquiring proficiency with these tools through practice and, if possible, guided instruction will significantly enhance the quality of your craftsmanship.

Planning and preparation are the bedrock of a successful wooden boat building project. Detailed blueprints and schematics should be meticulously developed before commencing construction.

This phase involves not only the design aspects but also logistical considerations, including workspace setup and time management. By investing adequate time in the planning stage, you can foresee and mitigate potential challenges, thereby streamlining the building process.

A list of essential supplies and tools for building a wooden boat includes:

· Tasmanian Huon Pine lumber (As You Would Imagine).

· Marine-grade plywood.

· Epoxy resin and hardeners.

· Stainless steel screws and fasteners.

· Hand saws and power saws.

· Chisels and planes.

· Clamps and sanders.

· Measuring tools (calipers, squares, rulers).

· Protective gear (gloves, goggles, masks).

By mastering these fundamentals and ensuring meticulous preparation, you set a solid foundation for crafting your dream wooden center console V-hull fishing boat.

The blend of skill, quality materials, and precise tools will culminate in a vessel that stands the test of time.

Understanding V-Hull Wooden Fishing Boat Construction.

A V-Hull design is characterized by its V-shaped cross-section, which is particularly advantageous for fishing boats.

This design is highly esteemed for its ability to slice through water, offering superior stability and handling in various water conditions.

The V-Hull’s sharp bow and deep midsection ensure that the boat can maintain balance and performance even in rough waters, making it a popular choice among fishing enthusiasts.

The stability of a V-Hull fishing boat is one of its most notable advantages. The V-shaped structure contributes to a lower center of gravity, which minimizes the risk of capsizing and enhances the overall safety of the vessel.

This is particularly beneficial when navigating choppy waters or when the boat is at rest, providing a steady platform for fishing activities.

In terms of handling, the V-Hull design excels in maneuverability. The sharp bow allows the boat to cut through waves effortlessly, reducing drag and improving speed.

This results in a smoother ride and better fuel efficiency, which are crucial factors for long fishing trips. The hydrodynamic efficiency of a V-Hull also means that it can handle higher speeds with ease, enabling anglers to reach their fishing spots more quickly.

Performance-wise, a V-Hull wooden fishing boat offers a blend of speed, stability, and comfort.

The deep V shape can handle heavy loads without compromising on buoyancy or maneuverability. This makes it an ideal choice for those who require a reliable and versatile vessel for their fishing expeditions.

For enthusiasts looking to construct their own wooden V-Hull fishing boat, there are various plans and kits available.

These resources provide detailed blueprints and step-by-step instructions, simplifying the building process. Kits often include pre-cut materials and essential components, ensuring that even novice builders can achieve professional-quality results.

By following these comprehensive guides, one can craft a durable and high-performing V-Hull wooden fishing boat using premium materials like Tasmanian Huon Pine.

Gathering Materials and Tools for Your Project.

Embarking on the journey of crafting a wooden center console V-Hull fishing boat requires meticulous planning, especially in gathering the necessary materials and tools.

At the heart of this project is the esteemed Tasmanian Huon Pine, renowned for its durability, resistance to rot, and exceptional workability.

The choice of material is paramount, not only for the aesthetic appeal but also for the longevity and performance of the boat.

To begin, you’ll need to source high-quality Tasmanian Huon Pine. This timber can be procured from specialized wood suppliers who focus on marine-grade lumber.

It is advisable to inspect the wood personally or request detailed photographs to ensure the grain and quality meet the stringent demands of boat building.

Other essential materials include marine-grade plywood, epoxy resin, fiberglass cloth, and stainless steel fasteners.

These components are crucial for reinforcing the structure and ensuring the boat’s resilience in a marine environment.

In terms of tools, a comprehensive set is required to tackle the intricacies of woodworking and boat construction.

Key tools include a table saw, jigsaw, and circular saw for precise cutting of the timber. Planes and chisels will be necessary for shaping and finishing the wood, while clamps will be indispensable for securing pieces during assembly.

A power drill with an assortment of bits, a router for edge work, and a sander to achieve a smooth finish are also essential.

Additionally, you will need a set of measuring tools such as a tape measure, square, and calipers to ensure accuracy.

When gathering these materials and tools, consider purchasing from reputable suppliers who specialize in boat building. This ensures that the products meet the necessary standards and specifications.

Investing in high-quality tools not only facilitates the construction process but also enhances the overall craftsmanship of your wooden center console V-Hull fishing boat.

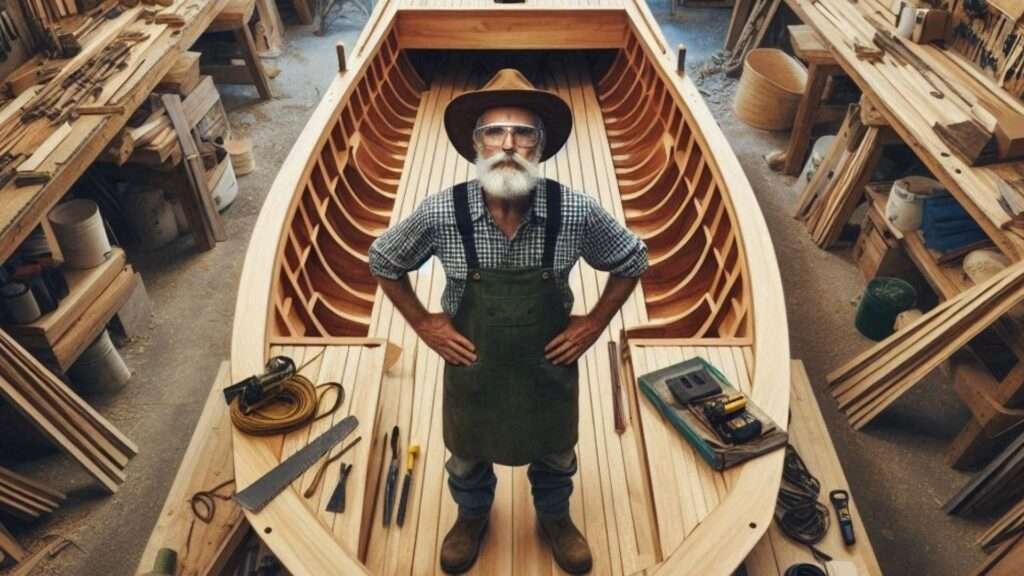

Step-by-Step Construction Guide.

Building a wooden center console V-Hull fishing boat using Tasmanian Huon Pine is an intricate yet rewarding process. To ensure a successful project, follow these detailed steps:

1. Gathering Materials and Tools.

Begin by acquiring all necessary materials, primarily Tasmanian Huon Pine for its durability and aesthetic appeal. Essential tools include saws, clamps, sandpaper, epoxy, and marine varnish.

Additionally, gather safety equipment like gloves, goggles, and masks to ensure a safe working environment.

2. Hull Preparation.

Start with the hull, the backbone of your boat. Cut the Huon Pine planks according to the design specifications. Use marine-grade plywood for the keel and frames.

Assemble the keel first, then attach frames at regular intervals. Once the skeleton is in place, affix the planking, ensuring each piece fits snugly.

Use clamps to hold the planks until the adhesive sets. Sand the surface to achieve a smooth finish.

3. Installing the Stringers and Bulkheads.

Next, install the stringers—longitudinal supports that reinforce the hull. Attach them securely using marine-grade epoxy.

Once the stringers are in place, install the bulkheads, which provide vertical support and shape to the boat.

Ensure all components align correctly to maintain the boat’s structural integrity.

4. Constructing the Deck.

With the hull complete, proceed to the deck. Cut the deck planks from Huon Pine and lay them over the stringers and bulkheads.

Secure each plank with screws and adhesive.

Be meticulous with measurements to avoid gaps. Sand the deck thoroughly and apply a coat of marine varnish for protection.

5. Assembling the Center Console.

The center console is the command center of your boat. Construct it using Huon Pine for consistency.

Begin with the base, ensuring it’s sturdy and level. Build the console’s framework, incorporating compartments for storage and electronic equipment.

Mount the steering wheel, throttle controls, and instrumentation and then secure all components firmly to withstand marine conditions.

6. Final Touches and Inspection.

Inspect the entire boat meticulously. Check for any loose fittings or rough edges. Sand any uneven surfaces and apply additional varnish coats where necessary.

Install seating, rod holders, and other accessories to enhance functionality. Conduct a thorough inspection to ensure the boat is seaworthy and safe for use.

By following these steps carefully, you can craft a stunning, functional wooden center console V-Hull fishing boat that showcases the beauty and resilience of Tasmanian Huon Pine.

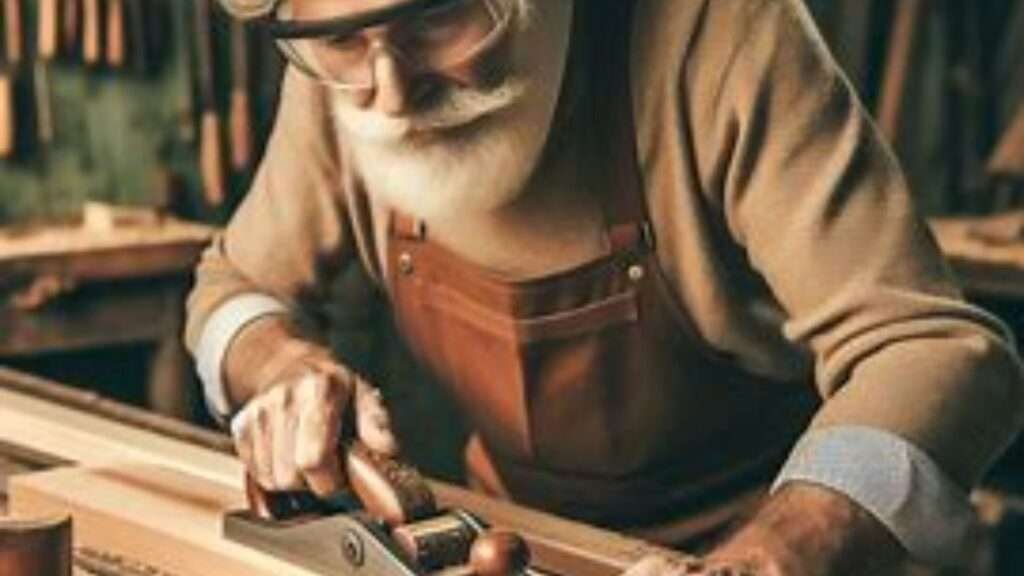

Ensuring a Quality Finish.

Achieving a high-quality finish on your wooden center console V-hull fishing boat made from Tasmanian Huon Pine is crucial for both aesthetics and durability.

The process involves several meticulous steps, each aimed at enhancing the natural beauty of the wood while providing robust protection against the elements.

The first step is sanding. Sanding smooths out any rough surfaces and prepares the wood for subsequent treatments.

Begin with a coarse-grit sandpaper, such as 80-grit, to remove any major imperfections.

Gradually progress to finer grits, like 120 and 220, to achieve a smooth, even surface.

Ensure you sand along the grain of the wood to avoid scratches and maintain the natural texture of the Tasmanian Huon Pine.

Once sanding is complete, the next step is varnishing. Selecting the right varnish is crucial; a high-quality marine varnish is recommended for its durability and resistance to UV rays.

Apply the varnish in thin, even coats using a high-quality brush or foam applicator. Allow each coat to dry thoroughly, and lightly sand with a fine-grit sandpaper between coats to ensure a smooth, professional finish.

Typically, three to five coats are sufficient to achieve a deep, lustrous finish.

Sealing is the final step in the finishing process. A good marine-grade sealer will provide an additional layer of protection, preventing moisture ingress and prolonging the life of the wood.

Select a sealer that is compatible with your varnish and apply it as per the manufacturer’s instructions.

This step is particularly important for Tasmanian Huon Pine, which, despite its natural resistance to rot and decay, benefits greatly from extra protection in a marine environment.

To achieve a professional look, pay attention to the finer details. Use painter’s tape to protect areas that should not be varnished or sealed.

Ensure your workspace is free from dust and debris, which can mar the finish. Lastly, take your time; rushing the process can lead to imperfections that detract from the overall appearance and durability of your boat.

Painting and Maintenance.

Maintaining the integrity and appearance of your wooden center console V-Hull fishing boat, particularly one crafted from Tasmanian Huon Pine, is paramount for both durability and aesthetic appeal.

One of the most critical aspects of this maintenance regimen is painting. Selecting the appropriate marine-grade paint is essential, as it must withstand the harsh marine environment, including exposure to saltwater, UV rays, and varying weather conditions.

Opt for high-quality, anti-fouling paints tailored specifically for wooden boats to prevent algae and barnacle growth, ensuring your boat remains in peak condition.

Proper application of marine-grade paint is equally important. Begin by thoroughly sanding the surface to remove any existing paint or varnish and to smooth out imperfections.

After sanding, clean the surface meticulously to eliminate dust and debris, which can affect paint adhesion.

Apply a primer first to ensure the paint adheres well to the wood. Follow this with at least two coats of your chosen marine-grade paint, allowing sufficient drying time between coats. For the best results, apply the paint in a controlled environment where temperature and humidity levels are stable.

Regular maintenance practices are vital to prolonging the life of your boat. A comprehensive cleaning routine should be established, involving freshwater rinses after each use to remove salt and grime.

Periodic inspections for any signs of damage, such as cracks, rot, or loose fittings, should be conducted diligently. Addressing these issues promptly can prevent more extensive damage and costly repairs down the line.

Additionally, periodic re-sealing or varnishing is recommended to protect the wood from moisture ingress and UV damage.

This process involves lightly sanding the existing finish and applying a fresh coat of marine varnish or sealant. Depending on usage and exposure, this may be necessary every 1-2 years.

By adhering to these guidelines and maintaining a regular schedule of upkeep, your Tasmanian Huon Pine wooden center console V-Hull fishing boat will remain in exceptional condition, offering you many years of enjoyable and reliable service on the water.

Final Touches and Launch Preparations.

As you approach the culmination of your boat-building journey, the final touches and launch preparations are crucial to ensure your wooden center console V-hull fishing boat is ready for its maiden voyage.

Begin by installing any additional features or accessories that will enhance both functionality and comfort. This may include rod holders, navigation lights, seating, and storage compartments.

The selection and installation of these components should align with your fishing needs and aesthetic preferences.

Once all accessories are in place, a thorough final inspection is essential. Carefully examine every aspect of your vessel to ensure there are no overlooked details.

Check for any loose fittings, ensure that all fastenings are secure, and verify that the hull is watertight. This stage also involves testing all systems, including the electrical and plumbing systems.

Make certain that the bilge pump, navigation lights, and any other installed equipment are operational.

Preparing the boat for its launch involves strategic planning and safety measures. Select a calm day for the launch to minimize potential complications. Prior to transportation, confirm that your trailer is in good condition and appropriately sized for your boat.

Double-check the trailer’s connection to your vehicle, ensuring all safety chains and lights are functional. When launching the boat, proceed slowly and steadily, keeping a close watch on the boat’s descent into the water.

Once afloat, take the time to perform a brief sea trial. This will help identify any immediate issues that may need attention.

Pay close attention to the boat’s handling, engine performance, and overall stability. Rectify any minor issues before heading out on longer fishing trips.

Completing a handcrafted wooden fishing boat is a significant achievement. The satisfaction and pride derived from building your own vessel from Tasmanian Huon Pine are unparalleled.

Enjoy the fruits of your labor, knowing that every detail has been crafted to your specifications, and embark on many successful fishing adventures ahead.