Woodshop Safety Information.

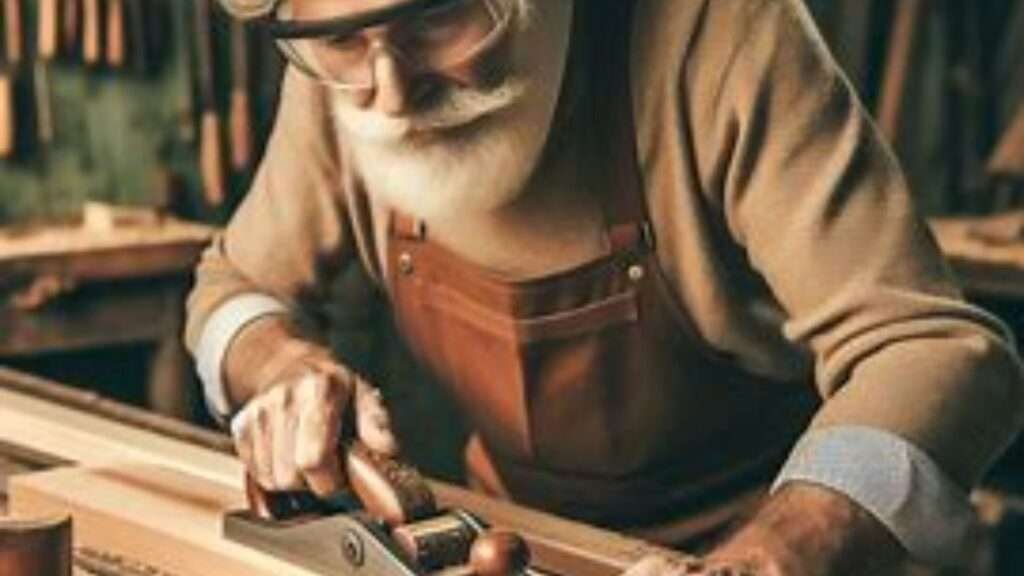

In the woodworking industry, the use of Personal Protective Equipment (PPE) is crucial in minimizing the risk of injuries and ensuring a safe working environment.

Each piece of PPE plays a vital role in protecting workers from the various hazards associated with woodworking tasks.

Safety goggles are indispensable for shielding the eyes from flying debris, wood chips, and dust.

They provide a clear line of sight while ensuring that any particulate matter does not cause eye injuries.

Given the high noise levels generated by machinery, hearing protection, such as earplugs or earmuffs, is essential to prevent hearing loss and other auditory issues.

Dust masks are another critical component of PPE in woodworking. They protect the respiratory system from inhaling fine wood particles and chemical fumes that can lead to respiratory conditions.

Workers should opt for masks that offer a snug fit and adhere to safety standards to ensure maximum protection.

Hand protection is equally important, with gloves serving as the first line of defense against cuts, abrasions, and chemical exposure.

Depending on the specific task, different types of gloves, such as cut-resistant or chemical-resistant, may be required to ensure optimal safety.

Appropriate footwear is also necessary to prevent foot injuries caused by falling objects, sharp tools, or heavy machinery.

Shoes with reinforced toes and slip-resistant soles are recommended to provide adequate protection and stability in the workshop.

The importance of PPE extends beyond individual safety; it is also a regulatory requirement that businesses must comply with.

To ensure adherence, regular training sessions should be conducted to educate workers on the correct usage and maintenance of PPE.

Additionally, management should implement strict protocols for monitoring compliance, including routine inspections and immediate corrective actions for any lapses.

By prioritizing the use of essential PPE, woodworking businesses can significantly reduce the incidence of workplace injuries, thereby fostering a safer, more productive work environment.

Safety Training and Refresher Courses.

In the realm of woodworking businesses, the cornerstone of a safe working environment is comprehensive safety training and periodic refresher courses.

The frequency and content of these training sessions are crucial to ensuring that all employees remain well-versed in the latest safety practices and regulations.

It is recommended that initial safety training be conducted during the onboarding process for new employees, followed by refresher courses at least annually, or more frequently if there are significant changes in safety regulations or the introduction of new equipment.

Effective safety training should encompass a range of topics tailored to the specific hazards of woodworking.

Key areas of focus should include the proper use of personal protective equipment (PPE), machine operation protocols, emergency response procedures, and hazard communication.

Additionally, employees should be educated on ergonomic practices to prevent injuries related to repetitive motion or poor posture.

Interactive training methods, such as hands-on demonstrations and practical workshops, can enhance the retention and application of safety knowledge.

Keeping employees updated on new safety practices and regulations is not only a regulatory requirement but also a proactive approach to risk management.

Regularly reviewing and updating the training materials ensures that the content remains relevant and comprehensive.

Incorporating recent case studies or industry-specific incidents can provide real-world context and underscore the importance of adhering to safety protocols.

A structured framework for conducting effective training sessions includes clear objectives, engaging delivery methods, and assessment tools to gauge understanding.

Tracking employee participation and performance is essential for maintaining compliance and identifying areas for improvement. Implementing a system for recording training completion and feedback can help in monitoring progress and planning future sessions.

By prioritizing continuous safety education, woodworking businesses can foster a culture of safety and minimize the risk of workplace accidents and injuries.

Operating Major Woodworking Machines.

Operating fixed-position woodworking machines requires strict adherence to safety protocols and operational procedures to ensure both efficiency and safety.

For table saws, the initial step is to verify that the blade is properly aligned and securely fastened. Always use a push stick when cutting narrow pieces to keep hands at a safe distance from the blade.

The startup procedure involves ensuring the blade guard is in place, the rip fence is locked, and that there are no obstructions on the table.

When shutting down, turn off the machine and wait for the blade to come to a complete stop before making any adjustments or removing cut pieces.

For band saws, check that the blade tension and tracking are correctly set according to the manufacturer’s specifications. The guide blocks should be adjusted closely to the blade without touching it.

When starting the band saw, ensure the blade guard is positioned properly and that the work area is clear. During shutdown, turn off the machine and wait for the blade to stop completely before making any changes.

Planers need special attention to feed rate and depth of cut settings. Before operation, inspect the knives for sharpness and secure mounting.

During startup, make sure the material is fed consistently and that the outfeed table is properly adjusted to support the workpiece.

Always turn off the planer and disconnect it from the power source before making any knife changes or adjustments.

Jointers require that the infeed and outfeed tables are aligned and that the cutter head guard is functioning correctly.

When starting the jointer, confirm that the fence is secure and that the workpiece is properly supported. For shutdown, turn off the machine and ensure all moving parts have stopped before making any adjustments.

In addition to these specific machine protocols, always conduct a general safety check before operating any woodworking equipment. Ensure that all emergency stop buttons are functional, that personal protective equipment (PPE) such as safety goggles and ear protection are worn, and that the workspace is free from any potential hazards.

Familiarity with these procedures and adherence to safety checks can significantly reduce the risk of accidents in a woodworking environment.

Emergency Shut-off Systems and Maintenance.

In the woodworking industry, the implementation of emergency shut-off systems is critical to safeguarding the well-being of employees and protecting machinery.

These systems are designed to halt the operation of equipment instantly in the event of a malfunction or hazard, thereby mitigating potential injuries and damage.

To ensure optimal performance, it is imperative that woodworking businesses prioritize the installation and regular maintenance of these safety mechanisms.

The first step in implementing an emergency shut-off system is to equip all machinery with easily accessible and clearly marked shut-off switches. These switches should be strategically located so that operators and bystanders can activate them without delay.

In addition, comprehensive training should be provided to all employees, ensuring they understand the functionality and location of these systems. This knowledge empowers workers to respond promptly during emergencies, potentially averting severe consequences.

Routine testing and maintenance of emergency shut-off systems are equally vital. Establishing a schedule for regular inspections helps identify and rectify any issues before they compromise safety.

These inspections should include checking the responsiveness of the shut-off switches, ensuring that wiring and connections are intact, and verifying that the system’s overall integrity is uncompromised.

Documentation of each inspection and any corrective actions taken should be meticulously maintained to track the system’s reliability over time.

In addition to mechanical upkeep, fostering a culture of safety among employees is essential. Clear protocols should be in place, outlining the steps to follow if an emergency shut-off is activated.

Workers should immediately cease all operations, notify supervisors, and evacuate the area if necessary. Regular drills and refresher courses can reinforce these procedures, ensuring that employees remain vigilant and prepared to respond effectively.

By integrating robust emergency shut-off systems and adhering to stringent maintenance protocols, woodworking businesses can significantly enhance workplace safety.

This proactive approach not only safeguards employees but also contributes to the longevity and efficiency of the machinery, ultimately supporting a safer and more productive working environment.

Tool Maintenance and Inspection.

Ensuring the safety and efficiency of a woodworking business hinges significantly on the consistent maintenance and inspection of tools.

Proper procedures for maintaining and inspecting a wide array of tools such as electric, battery-powered and all hand tools are essential to prevent accidents and prolong the lifespan of the equipment.

Regular maintenance is not merely a best practice but a crucial element in safeguarding workers and maintaining productivity.

Electric tools, such as saws, drills, and sanders, require particular attention. Regularly check for frayed cords, damaged plugs, and ensure all safety guards are functioning correctly.

The internal components should be cleaned periodically to prevent dust buildup, which can cause overheating and potential malfunctions.

Lubrication of moving parts, where applicable, should also be part of the maintenance routine.

Battery-powered tools, including cordless drills and saws, need their batteries inspected and maintained.

Check batteries for any signs of damage or leakage and ensure they are properly charged and stored. Overcharging or exposure to extreme temperatures can significantly reduce battery life.

Cleaning the battery contacts and ensuring they are free of debris can also help maintain optimal performance.

Hand tools, such as chisels, hammers, and screwdrivers, although seemingly straightforward, also require regular inspection.

Check for signs of wear and tear, such as cracks or chips in the handles and blades. Sharpening blades and ensuring handles are securely attached can prevent accidents and ensure the tools’ effectiveness.

To streamline the maintenance process, a routine inspection checklist can be invaluable:

1. Inspect cords and plugs for wear and damage.

2. Check battery condition and charge levels.

3. Clean and lubricate tool components.

4. Ensure safety guards and features are operational.

5. Sharpen blades and check tool handles for integrity.

Implementing a regular maintenance schedule not only enhances tool longevity but significantly reduces the risk of accidents, ensuring a safer working environment for all employees.

By adhering to these practices, woodworking businesses can maintain high standards of safety and efficiency.

Handling and Storage of Raw Materials.

Proper handling and storage of raw materials, such as lumber and plywood, are crucial for maintaining a safe woodworking environment.

Ensuring that these materials are accessed and stored correctly can significantly reduce the risk of accidents and injuries.

Firstly, organizing wood storage areas is essential. Materials should be stored in a manner that prevents them from falling or causing obstruction. Racks and shelving units should be sturdy and capable of supporting the weight of the stored materials.

Proper labeling of different types of wood can also help in quickly identifying and accessing the required materials without unnecessary handling.

When lifting heavy materials, it is important to use proper techniques to avoid strain and injury. Always bend at the knees and keep the back straight while lifting.

If the load is too heavy or awkward to handle alone, seek assistance or use material handling equipment such as forklifts or hand trucks.

Utilizing these tools not only ensures safety but also enhances efficiency in material handling.

Material handling equipment should be inspected regularly to ensure it is in good working condition.

Operators must be trained in the safe use of this equipment to prevent accidents. Additionally, maintaining clear pathways in storage areas can prevent trips and falls, facilitating easier and safer movement of materials.

Moreover, it is important to store materials away from moisture and direct sunlight to prevent warping and degradation.

Keeping the storage area clean and free from debris can also prevent accidents and improve overall safety.

Implementing these best practices will not only safeguard the well-being of workers but also contribute to the longevity and quality of the raw materials.

Dust Collection and Ventilation Systems.

Maintaining effective dust collection and ventilation systems is paramount in ensuring a safe working environment for any woodworking business.

Wood dust, often generated during sawing, sanding, and milling processes, poses significant health risks if not properly managed.

Prolonged exposure to wood dust can lead to respiratory issues, skin irritation, and more severe conditions like occupational asthma and even cancer. Therefore, implementing a robust dust collection and ventilation system is critical for safeguarding the health of workers.

Setting up a dust collection system involves selecting the appropriate equipment tailored to the specific needs of your workshop.

Centralized dust collection systems are often recommended for larger operations, as they can handle a higher volume of dust and connect to multiple machines. Portable dust collectors, on the other hand, are suitable for smaller setups or specific tasks.

Ensure that the dust collectors have sufficient capacity and are equipped with high-efficiency particulate air (HEPA) filters to capture fine dust particles effectively.

Ventilation systems complement dust collection efforts by maintaining air quality within the workshop.

Proper ventilation ensures that airborne dust particles are continuously removed from the environment, reducing inhalation risks.

Installing an exhaust ventilation system that directs dust-laden air outside the workspace can significantly enhance air quality.

Additionally, make use of air purifiers with HEPA filters to further clean the indoor air and provide a healthier breathing environment.

Regular maintenance of dust collection and ventilation systems is essential to ensure their efficiency. This includes routine inspections, cleaning filters, and checking for any blockages in the ductwork.

Periodically replacing worn-out components will also contribute to the longevity and effectiveness of the systems. Educating employees on the proper use and maintenance of these systems can promote a culture of safety and prevent potential hazards.

To mitigate the health risks associated with wood dust, it is also advisable to implement best practices such as using personal protective equipment (PPE) like masks and gloves, and adhering to stringent housekeeping protocols.

By prioritizing dust collection and ventilation, woodworking businesses can create a safer and healthier workplace, ultimately enhancing productivity and employee well-being.

General Safety Rules For Woodworking.

Wear hearing protection when working in an environment that requires you to raise your voice to communicate with others.

At 85 dB(A), you will typically have to raise your voice, while at 90 dB(A), you will have to shout to be heard. Prolonged exposure to noise levels above 85 dB(A) causes significant hearing damage.

Before being used, all chemicals must have a Material Safety Data Sheet (MSDS) and should be reviewed through Chemwatch.

Keep clear of any person operating tools and machinery and refrain from talking to them unless urgent, bumping into or distracting an operator could cause serious injury to you or the operator

Check that the work area you’re about to use is free of hazards, and make sure to keep it tidy, clean and safe for the next person.

Is there a fully charged fire extinguisher and/or well-stocked first-aid kit within close proximity, just in case things go wrong?

Always give your complete focus to the task at hand and maintain secure footing and balance.

Clamps or a vice should be used to hold your work wherever possible, always double-check that your work-piece is properly secured before starting.

Keep flammable liquids in a certified flammable storage cabinet. Examples include paints, solvents, petrol, kerosene, thinners, turpentine, white spirits, pine oil, and linseed oil.

General Woodworking Electrical Equipment/Tool Safety.

Keep leads up off the floor get tangled in a stray lead could cause serious injury.

Protect yourself against electric shock by adding a residual current device (RCD or safety switch) to the electrical circuit. Use a portable RCD if an RCD is not installed.

Electric instruments should be kept away from oil, hot surfaces, and chemicals and not be used in moist areas or where combustible gases or vapours are present.

Treat all electrical devices as if they are live or energized.

Never use wet hands to operate switches or other electrical appliances, such as sockets. This is because a wet body can act as an excellent conductor of electricity, resulting in an electrocution.

Even if there is no visible physical injury, an electric shock can cause internal harm. Even minor electric shocks require medical attention to determine whether they have harmed the heart. Always take anyone who has been shocked to the nearest emergency room for examination.

Power Tools & Equipment – General Safety.

Read the operator’s manual for all equipment and follow all safety measures.

Know how to use the tools properly and safely, ask questions if you’re unsure.

Are your power tools and equipment in good condition and properly guarded? Any damaged or broken equipment or guarding must be set aside and tagged that they are ‘out of service’.

Avoid wearing shirts with long sleeves unless you roll them up, and remove any jewellery such as rings, necklaces, or bracelets before working with power tools.

Allow each power tool to work at its own pace, do not force them.

Tie back long hair to prevent it from getting caught in your equipment.

If a power tool stalls or jams immediately turn it off.

Power tools should be stored carefully to avoid damage to the tool or cable.

Turn off all machinery before making adjustments.

Table/Contractor Saw Safety:

1. Wear Safety Glasses.

2. Wear hearing protection.

3. Wood must always be secured firmly down.

4. Keep hands/fingers away from saw blades.

5. Never adjust saw or set-up while saw is running.

6. Always use a push stick, you can make one from scrap.

7. Never attempt freehand cuts. The wood must always be firmly secured against the rip fence (a guide bar parallel to the saw blade).

8. Use the mitre gauge for making crosscuts, hold work pieces securely at a set angle.

9. Blade guards that encase the blade while it is cutting must be intact and not damaged as they provide you with protection and are to make sure your fingers don’t come into contact with the blade.

Mitre Saw Safety:

1. Wear a face shield, or safety goggles/glasses.

2. Use dust extraction and/or wear a respirator or dust mask.

3. Wear hearing protection.

Scroll Saw Safety:

1. When using a scroll saw, never wear gloves unless they are tight fitting, or loose clothing.

2. Take off any watches or jewellery.

3. Long hair should be tied up and back.

4. Make sure the belt guard is intact, closed up and secured before operating.

5. Always use the appropriate saw blade for the job.

Drill Press Safety:

1. Wear tight-fitting clothing and gloves and tie back long hair as you don’t want anything getting caught up in the bit or spindle.

2. Never attempt any form of set-up or adjustments while the drill is operating and never start a drill with the chuck key still in place.

Thickness Planer Safety:

1. Do not wear loose clothing, remove any jewellery, or wear watches.

2. Roll up your sleeves if you’re wearing a long sleeved shirt.

3. When using a planer, avoid wearing gloves unless they are tightly fitting.

4. When the wood is in the planer, don’t raise or lower the table.

5. Wear a dust mask, eye and ear protection, and run dust collection at all times.

6. Always try to plane with the grain as opposed to against it to avoid the wood tearing out.

Router Safety:

1. When using a router freehand, make sure the work-piece is securely clamped to your bench or work table.

2. Keep your hands and fingers away from the bit at all times, and always hold the router with both hands until the motor has stopped.

3. Never make any changes to a router without first unplugging it.

4. Inspect the bit for damage or visible dullness after you’ve chosen it.

5. Wear eye and ear protection, as well as a dust mask or respirator, and connect your router to a dust vacuum or extractor.

Hand Tools Safety:

1. Maintain the cleanliness and sharpness of your tools.

2. Wear safety glasses when using punches, chisels, hammers, or grinding tools.

3. Use only tools designed for the job and not handmade or altered tools.

4. Keep no pointy or sharp tools in your pockets.

5. Check that you have enough light to see what you’re doing; if you need more, simply ask.

6. Use tools that are the correct size and shape for the job.

7. Instead of holding a small part in your hand while working on it with a screwdriver, use a vice.

8. Use a chisel with a cutting edge the same width as or wider than the area to be cut, and the largest punch that will suffice without binding for the job.

9. Chisels and punches should be held loosely in the palm of your hand with the palm up, or a tool holder can be utilised.

10. When using chisels and punches with mushroomed heads, use caution since metal can chip off and cause injury.

11. Instead of using a chisel, punch, or pry bar to remove gears, wheels, or bearings off a shaft, use a pulling tool.

12. Do not use a hammer with a fractured head or handle, or one with a mushroomed striking face.

13. Wipe oil, grease, and filth from tools using a clean rag before starting a project.

[…] https://www.glzwoodw.biz/woodshop-safety/ […]