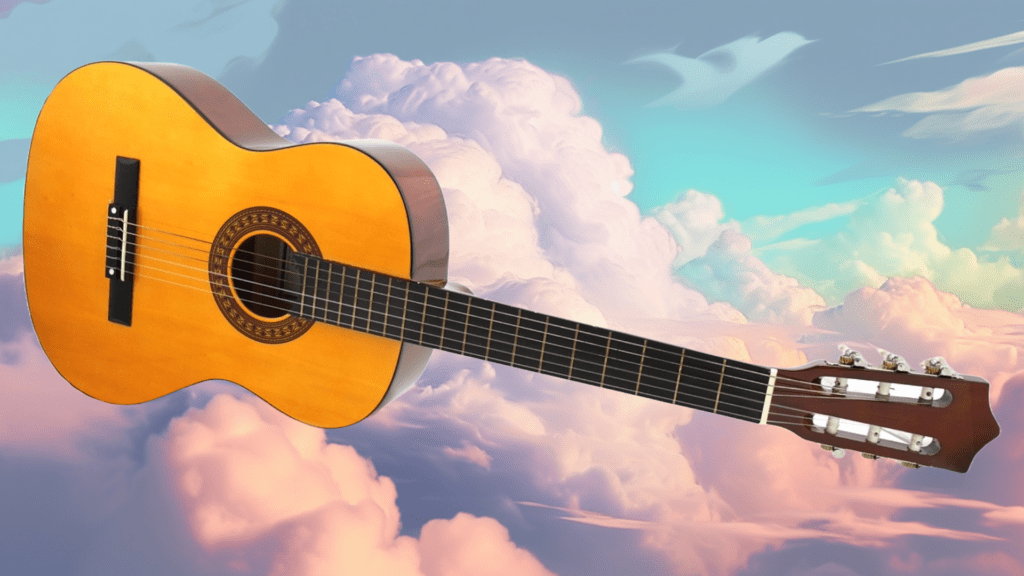

Make Your Own great Classical Guitar

Building your own wooden classical style guitar

can be a great fun and rewarding project for any music enthusiast who likes to

dabble with woodworking occasionally. Not only will you have the satisfaction

of creating something with your own hands, but you will also hopefully have a guitar

that you love and you’ve made according to your preferences and playing style. Not to mention, it’ll be something you can

brag about to friends and/or band members.

In this article, I will try my best to walk you

through the process of building your own guitar, from selecting the materials

to assembling the final product.

Materials and Tools you will

need.

Before you begin, gather all the necessary

materials and tools:

a.

Wood for the body, neck, and

fretboard (common choices include spruce, cedar, and mahogany)

b.

Guitar bracing

c.

Bridge and saddle

d.

Machine heads

e.

Nut and frets

f.

Glue

g.

Sandpaper

h.

Clamps

i.

Chisels

j.

Files

k.

Saws

l.

Drill

m. Ruler

Step Number 1: Design and Plan.

Start by designing your guitar. Consider the

shape, size, and style that you prefer. Classical guitars typically have a

smaller body and a wider neck compared to other guitar types. Sketch your

design on graph paper and make sure to include measurements and dimensions. You might also be able to download a free

open source plan for building your own guitar.

Let Us Begin.

Overview.

1.

Choose high-quality wood for your

guitar. Cut the body, neck, and fretboard according to your design. Ensure that

the wood is properly seasoned and free from defects. Use sandpaper to smooth

the surfaces and remove any rough edges.

2.

Assemble the body of the guitar

by gluing the sides to the back and then attaching the top. Use clamps to hold

the pieces together firmly while the glue dries. Once the body is dry, shape it

to the desired contours using chisels and files.

You will need to create a blank for the body and

the most popular varieties of wood used to make a blank for the body of a

guitar are Mahogany, Ash, Maple, Basswood, Alder, Poplar, Walnut, and

Spruce. Making a guitars from Agathis is

an option and there’s plenty of guitars in this world that are made from

Agathis; however I’ve read a few unfavourable articles about how the noise is

dulled from using this type of wood.

Constructing the Body.

Overview: Assemble the body of the guitar by

gluing the sides to the back and then attaching the top. Use clamps to hold the

pieces together firmly while the glue dries. Once the body is dry, shape it to the

desired contours using chisels and files.

The Process.

Once you’ve settled on the shape of the guitar and

have a comprehensive drawing of the guitar you want to create, cut out a

template for the body from 3/4″ (20mm) MDF. Make two copies of your drawing:

one for later cutting up and one as the master; study all features of your

drawing several times; it will be worth it in the end. To get a drawing that

big replicated, you’ll need to go to a professional copying business (they’ll

presumably use a ‘Plotter’ style printer), or you might know someone who has

one.

By tracing the contour of your body from your ‘cut

up’ copy of your design onto your MDF board with your pencil, you can now

acquire the outline of your body. The centre line is crucial; once you’ve drawn

it with a pencil on your MDF board, go over it with a thin-tipped permanent

marker. Before you trace the drawing, make sure it’s centred along the centre

line you’ve just made with your ruler. You can now roughly cut out the shape

with whatever tool you want, trying to stay as close to the black line as

possible without going into it. Stay a couple of mm away from the line because

you can always remove material you didn’t cut away later, but you can’t add

back material you took away inside the line.

You now have a rough shape for your body that

needs some work, so we’ll use sanders to refine it. If you have an Oscillating

Spindle Sander (OSS), use it to make a continuous, perfectly flowing curve on

all of the template’s concave regions. If you don’t have an OSS, make do with

what you have or can afford. Instead of sitting and sanding the board in one

spot, move the template along the curve as you sand it. Only if you have a

significant lump that needs to be brought down to level with the curve should

you sand a region without moving. This repeated sanding process will assist in

perfecting the curve and making it smooth and consistent.

It’s now time to work on the convex areas of the

template now that you’ve completed and approved the concave regions. We’ll use

the palm sander for this and the reason for this is that it has a flat bottom

surface, which means it will sand off all high points but won’t sand lower and

lower spots because it’s flat and the surface is convex, resulting in some

wonderful uniformity. Sand the convex portions using the same method of testing

your progress with light profiles until they, too, flow flawlessly and you are

satisfied.

Create your template for the headstock shape using

the same procedures as before, then continue on to the final template you’ll

need to make, which is the template for your neck and fretboard. You can use

the same template for the fretboard as you did for the neck. Simply measure the width of the neck at the

nut and at any point further down the neck, say the 12th or 24th fret for

convenience, and then tape a perfectly straight piece of wood along one edge of

the taper you’ve drawn out between the nut and the point you chose further down

the neck with strong double sided tape.

Use a template bearing guided router bit to route

down this straight piece, then repeat for the other side of the fretboard

taper, and you’ll have a wonderful neck and fretboard taper. Now is the time to

cut out the excess wood where the nut will go, as well as the end of your neck

tenon. If you want to use a router to route your neck pocket, round off the

ends of the template so that the tenon end is at the same radius as the router

bit. This will provide a beautiful tight fit.

This template can be used to route the entire neck

or just the fretboard by placing the fretboard wood at the nut and then centre

it. There are many various ways to create a guitar neck and fretboard;

practically all electric guitar fret boards have some form of radius, and

different people prefer different radiuses.

Making a guitar can potentially necessitate

spending a lot of money on specialist tools, which may be necessary if you want

perfection and time is a concern, but if you’re attentive and meticulous, you

can make an outstanding guitar on a very small budget. Remember, people made

guitars a long time ago, long before any of the sophisticated equipment we have

today were ever considered; in fact, the first guitars are said to have been

invented in Spain in the 15th century.

The final shaping of the neck and headstock is

also a matter of personal preference; the majority of the shaping may be done

using an angle grinder and a carving wheel, then everything can be perfected

with hand sanding. The fretboard is a delicate task that demands extreme

precision and accuracy. Fill up the little holes drilled on the edge of the

fretboard for the side dots that identify individual frets with epoxy.

If you want to take a break from the fretboard,

finish shaping the body of the guitar by carving a contour on the back and

cutting a bevel on the front, both of which will make playing the guitar much

more comfortable.

Installing the Neck.

Attach the neck to the body using glue and clamps.

Make sure the neck is aligned properly and securely fastened. Use a ruler and

level to ensure it is straight. Allow the glue to dry completely before moving

on to the next step.

Installing the Fretboard and

Frets.

Glue the fretboard onto the neck and secure it

with clamps. Once dry, mark the positions for the frets using a fret spacing

calculator. Cut slots for the frets and install them using a fret press or

hammer. Trim any excess fret wire and file the edges smooth.

Installing the Bridge and Saddle.

Attach the bridge to the body at the designated

location. Install the saddle into the bridge slot and adjust its height for

proper string action. This will affect the playability and sound of the guitar,

so take your time to get it right.

Installing the Machine Heads and

Nut.

Drill holes for the machine heads on the

headstock. Insert the machine heads and tighten them securely. Install the nut

at the top of the fretboard, ensuring the strings sit properly in the slots.

Do the finishing touches.

Sand the entire guitar to smooth out any

imperfections. Apply a finish of your choice to protect the wood and enhance

its appearance. Allow the finish to dry completely before installing the

strings.

Stringing and Set-up.

Attach the strings to the machine heads and tune

them to the desired pitch. Adjust the truss rod, bridge height, and saddle

position to achieve proper string action and intonation. This may require some

trial and error, so be patient and make small adjustments.

Please Note:

There is a number of steps that I will endeavour

to expand on sometime soon and apologise that I couldn’t provide the complete

process via this article.

However, you could always have a look on

YouTube. You’re more than likely going

to find a video that will walk you through the gaps that I have left in the

process.

In any event, building your own wooden classical

style guitar will no doubt prove to be a labour of love. Sure, this work is going to require a lot of

patience, reasonable skill, and attention to detail but if you pace yourself

and be prepared you might make the odd mistake and not be afraid about re-doing

things a few times, you’ll get there.

Naturally, it’s just so important that you use the

right materials and tools. If it all

goes well, you can create a beautiful and functional instrument that will bring

joy for years to come. Enjoy the process and the satisfaction of playing music

on an instrument you built with your own hands.